How Sheroz Earthworks can Save You Time, Stress, and Money.

How Sheroz Earthworks can Save You Time, Stress, and Money.

Blog Article

Sheroz Earthworks - Questions

Table of ContentsThe Facts About Sheroz Earthworks UncoveredWhat Does Sheroz Earthworks Mean?The Facts About Sheroz Earthworks RevealedSheroz Earthworks - An OverviewThe 8-Second Trick For Sheroz Earthworks

For any type of earthwork service provider, it is essential to carry out deal with quality, precision, and on time. Utilizing equipment control in job devices enables maximizing the various phases in the earthwork procedure, from preparing to the maintenance stage - trimble parts. The machine control system aids the device driver in attaining the target aircraft swiftly and easily

The device control system overviews the operator with centimeter accuracy. Remote support saves time and money, as it decreases downtime in jobsites.

Sheroz Earthworks - An Overview

Our system's components are meticulously developed to hold up against the rough conditions of building sites. Comparison of the same project executed utilizing equipment control versus the typical technique reveals that, on average, the standard method calls for 50% even more time to achieve the same job as the technology-assisted method.

Get in the Xsite device control system; it's here to give you with a considerable advantage when working with earthmoving machinery. Discover how Xsite Equipment Control can improve your performance and ensure work safety! Xsite Device Control systems can be set up to any excavator from mini excavators to big mining excavators.

Just how does machine control work? In 2D systems, the maker is outfitted with adjusted disposition sensors. These sensing units are placed on the pre-determined components of the equipment in excavators the sensor are generally placed to the frame, boom (or booms), miner arm and to the fast coupler - fj dynamics auto steering kit price. By making use of the data received from these sensing units the system can calculate the exact position of the excavators pail idea in importance to a reference factor.

The system is very easy to learn the essentials can be taught in under one hour of training. Exactly how does the remote assistance work? Discover More A cordless net connection makes it feasible to establish a remote connection in between the machine control system and the solution.

Some Known Details About Sheroz Earthworks

What kind of information styles Xsite systems assistance? Xsite Equipment Control systems support open common data formats, allowing smooth info circulation from one system to one more. Sustained data styles: 2D-Maps: DXF Factor files: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Area Versions: DXF, XML What parts are installed on my machine? Depending upon your option of system (with or without positioning, i.e - topcon laser level., 2D or 3D), your device is geared up with inclination sensors, a controller device, and a display/operating panel.

Many hardware and software program solutions exist to assist figure out a machine's current placement on the earth and compare it with a preferred style surfaceand building operators can do more to leverage the benefits. Machine control is the use of various placing sensing units and a display screen to offer the driver with a reference in between the setting of the container or blade and the target quality.

Depending upon the arrangement, machine control systems can provide the operator with an easy aesthetic overview to bucket or blade setting, or can instantly move the blade to grade by speaking with the device's hydraulics - https://lwccareers.lindsey.edu/profiles/5240299-floyd-overbeck. There are maker control systems available for just about any type of equipment: , dozers, excavators, soil and asphalt compactors, scrapes, leaners, grating devices, and pavers

Some Ideas on Sheroz Earthworks You Should Know

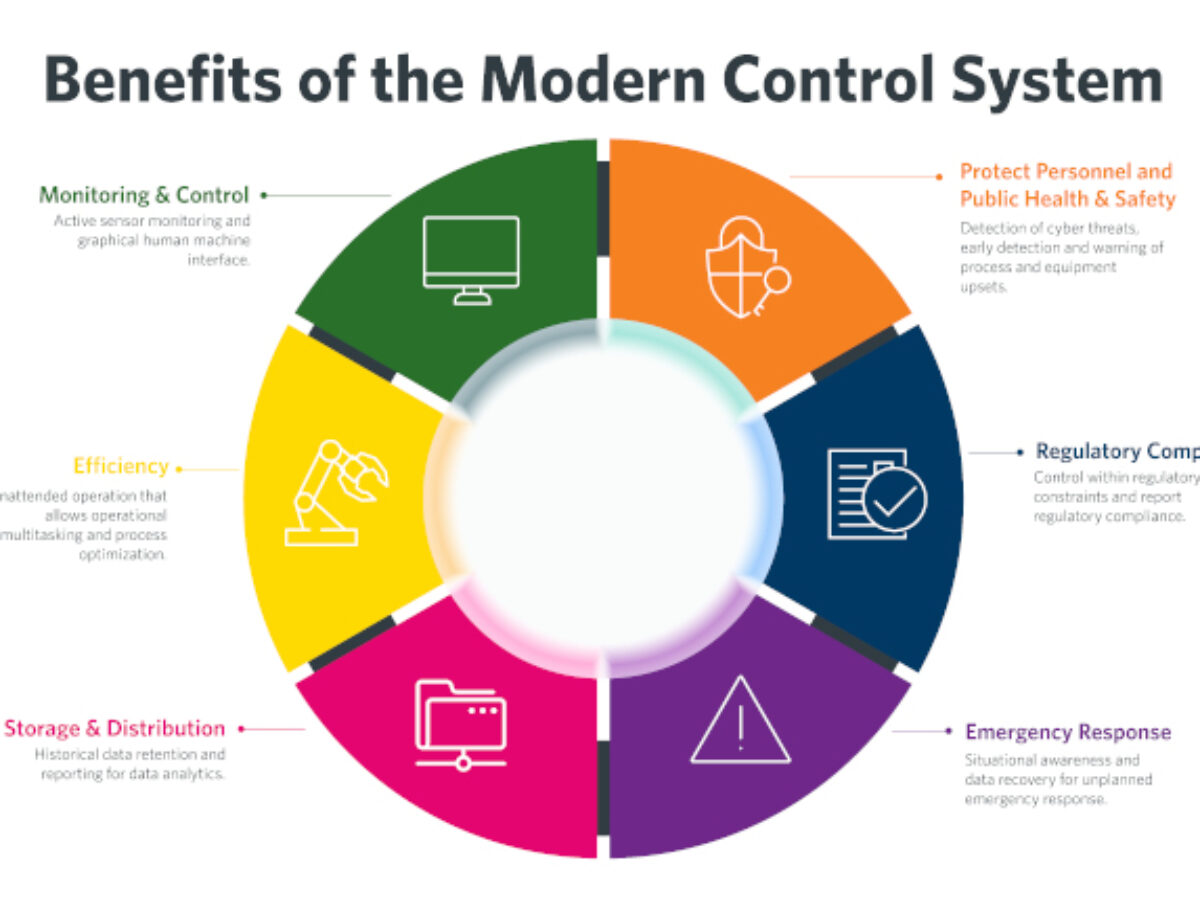

Some benefits consist of reduced rework, improved work performance, and reduced evaluating costs. Maker control can likewise assist increase productivity and reduce overall costs. This technology is transforming the means the construction sector works. Building tools without maker control will become a distant memory and the advantages gained from it will certainly be many.

Trimble maker control systems provide a myriad of advantages to any person that makes use of earthwork equipment and, at EarthCalc, we can offer you with 3D apply for your device control-enable equipment. Unsure if equipment control deserves the cost? Take into consideration the adhering to reasons why you need to consider this alternative.

Making use of general practitioner aligned with your 3D layout documents, these systems practically ensure that you will certainly eliminate or position the right amount of material at the construction website. On most building websites, revamp is a typical and irritating truth, however with Trimble device control, you can eliminate the demand for rework.

Top Guidelines Of Sheroz Earthworks

Often, with Trimble maker control, you can remove excess equipment at a certain task website. A job that may have called for the use of three or 4 items of digging deep into equipment currently could require just 2 items of devices to complete the exact same task in less time. This permits you to relocate your tools to an additional work site and handle numerous jobs at once.

Report this page